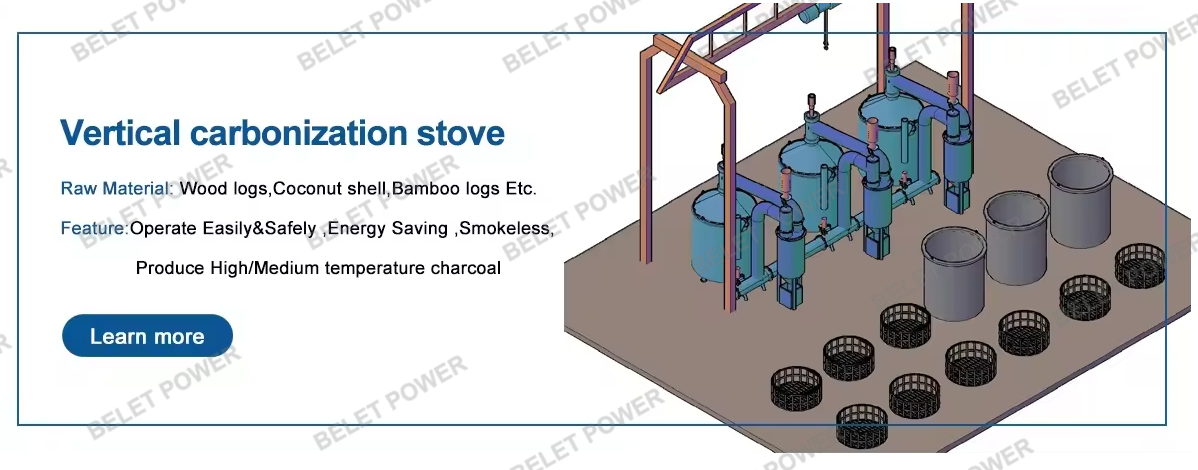

Vertical Carbonization Furnace

Production description

The vertical carbonization furnace is made of high temperature material by using high-tech environmental purification technology, which is durable without oxidation or deformation. The airflow carbonization furnace has the advantages of good insulation, simple operation, safe and reliable performance, and the dual chimneys can get materials carbonized fully with qualified rate more than 95%, saving time and labor with a person being able to operate several carbonization furnaces.

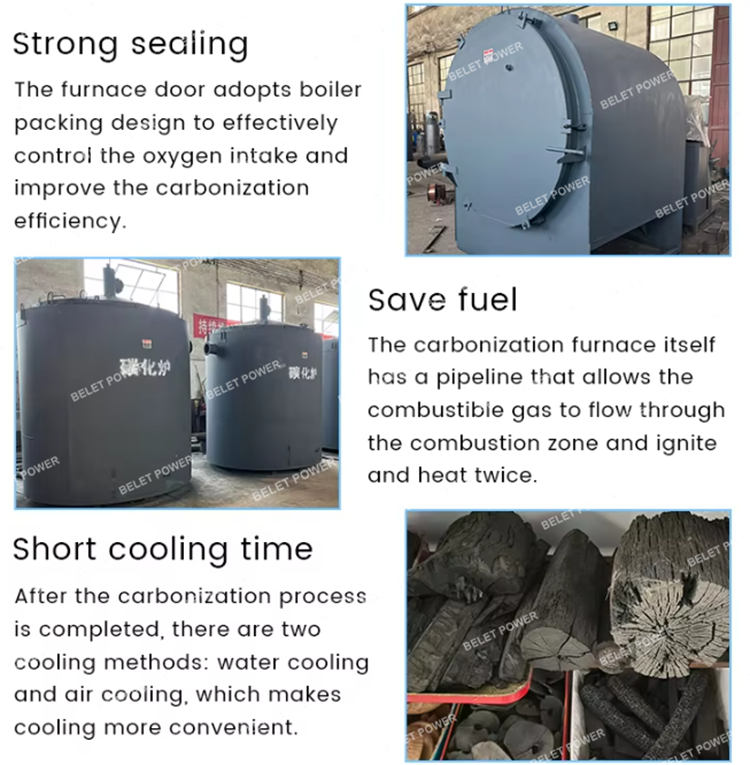

Main Feature

1. High carbonization rate, no smokeless, little pollution, high efficiency

2. Newly developed carbonization kiln, which can dry the materials with the superfluous energy produced in the charring process.6-8 hours per stove and can work continuously.

3. The tube of smokeless extraction will recycle the gas-flow which come from the carbon basket during the charring process for continue warming the stove, and it will save 70% energy consumption and recycle 95% smokeless.

4. It can connect to the drying equipment directly to get more heating to dry the powder.

The vertical carbonization furnace also adopts high-tech purification technology. It is made of special high-temperature resistant precious metal steel. It is strong and durable, does not deform, does not oxidize, has good thermal insulation performance, is easy to operate, safe and reliable, and has no carbonization dead corners.

1. The furnace has a 3m3 solution, the raw material carbonization rate is more than 40-60%, and the finished product rate is more than 95%.

2. It saves labor and time. One person can operate several carbonization furnaces at the same time. No need to worry about being too busy

Working principle

1. The drying stage. Put the wood in the inner tank, after ignition, the temperature reaches about 160 ° C, and the moisture is basically completed.

2. The pyrolysis stage. When the temperature reaches between 170 ° C and 280 ° C, the wood pyrolysis reaction occurs, at which time the unstable components such as hemicellulose decompose. This stage takes about 2 hours and 30 minutes.

3. Full carbonization stage. When the temperature in the furnace reaches about 300 ° C, flammable gas will be produced. The gas enters the combustion chamber and can be burned again, at which time fuel can be saved. The temperature reaches about 380℃-400℃, and the wood is retorted into carbon at high temperature. This phase takes about 2 hours. Cooling out phase.

4. After carbonization. The inner furnace is cooled naturally. It should be noted that the lid cannot be opened immediately, which can easily cause an open flame. When the temperature drops to about 50°C, it is ideal to open the lid to produce carbon.

My advantage

1. Achieve efficient, stable and safe carbonization process.

2. Save time and labor, easy to operate, save raw materials.

3. The production of high quality charcoal has a broader application prospect.

The Final products

Production Application

1. Charcoal carbonization furnace is an ideal equipment for making high quality charcoal. It is widely suitable for large range of raw materials. Such as wood log, wood branches, wood chips, sawdust briquette, rice husk /hull, coconut shell, palm kernel shell, olive shell, coffee shell, straws, bagasse etc. After carbonization, the raw material will become final charcoal.

2. The heating methods can be burning wood, coal, diesel oil, natural gas, LPG, etc.

It is easy to be used for materials with large, and the use of advanced carbonization technology ensures that the entire process does not produce harmful gases and does not pollute the environment.