Solid Waste Disposal Machine

This double shaft shredder for garbage is widely used in waste plastics, waste rubber, wood and other bulky waste. The double shaft shredder have been improved, researched and developed with mature technology and advanced design based on more than 30 years of experience in manufacturing such equipment in Europe and America, and improving according to the actual situation in China, which is the reliable equipment for crushing and recycling of waste in China.

The technical parameters:

Model | Blade Diameter | Spindle Diameter | Motor Model | Length*Width*Height |

600 | 220mm | 100mm | 11kwx2 | 2500*1100*1600 |

800 | 260mm | 140mm | 18.5kwx2 | 3100*1600*2100 |

800 | 400mm | 180mm | 30kwx2 | 3700*1800*2200 |

800 | 400mm | 180mm | 30kwx2 | 3700*1800*2200 |

1000 | 450mm | 220mm | 37kwx2 | 4200*2100*2800 |

1200 | 450mm | 220mm | 45kwx2 | 4450*2200*3200 |

1400 | 500mm | 240mm | 55kwx2 | 4800*2300*3300 |

1600 | 500mm | 240mm | 75kwx2 | 5200*2400*3400 |

1800 | 550mm | 280mm | 110kwx2 | 5600*2600*3500 |

2000 | 600mm | 320mm | 132kwx2 | 6000*2800*3600 |

The structure:

The double shaft shredder is a machine composed of a shredding blade group, a bearing box, a box bracket, a feeding system, a power system, and an electrical control system. It can be configured with in feed conveying, out feed conveying and magnetic separation equipment.

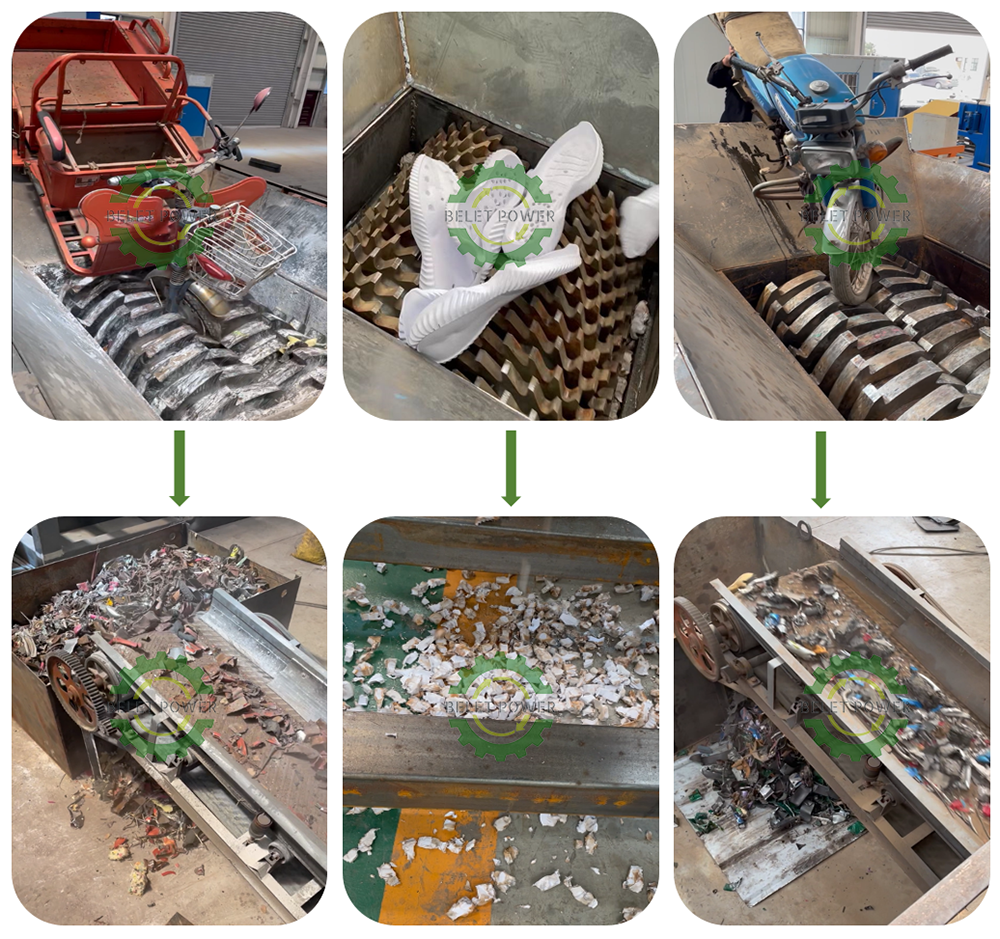

Raw materials:

1. A variety of hollow containers: plastic beverage cans, plastic buckets, iron, cans, packing boxes.

2. Waste household appliances: TV, washing machine, refrigerator shell.

3. Pipe: large pipes, pipe fittings, PE pipe.

4. Waste template: wooden pallets, plastic pallets, truck pallet.

5. Waste tires: car tires, truck tires.

6. Scrap metal: car shell, aluminum die casting scraps, engine shell, gear boxes, lead as well as the steel plate with less than 5mm thickness.

7. Textile: scrap clothes, shoes, fishing net, woven bag, ton bag, jumbo bag, fishing net bundles, dust collector bag, industrial textile waste.

8. The food waste: garbage, animal carcasses, RDF derivatives, medial waste, biological straw, garden garbage.

The features:

1. Heavy-duty construction and efficient performance are determined by the precisely processed combined frame made of extra-thick plates.

2. Wide angle, hexagonal prism of power slewing axis; large hopper with big caliber for feeding large material.

3. It adopts PLC control system, automatic overload protection and auto reverse switch.

4. The low rotation speed results in a particularly quiet shredding process with low levels of dust generation.

5. It can be adjusted according to customer specific requirements for throughput volume, material to be processed.

The advantages:

1. Double blade shaft mechanism, using multiple multi jaw cutting tools and coordinating with the tool shaft for multi angle changes, saving cutting effort, strong cutting force, and demonstrating strong crushing ability.

2. The motor passes through the gearbox transmission system to create a transmission structure, making it operate at low speed and high torque, achieving a crushing effect.

3. The large transmission wheel is made of special steel and has undergone heat treatment hardening, resulting in a long service life.

4. The gearbox adopts an oil inlet pulley, which operates smoothly, has low noise, high torque, and is resistant to long-term operation.

5. The design of low speed and high torque provides lower noise and less dust, improving a good working environment.

Production process:

The working process of a double shaft shredder for garbage is usually divided into three stages: feeding, shredding and discharging. When the material is put into the feed port of the shredder, the feeding system will evenly distribute it to the two rotating shafts. Then, the cutter shaft starts to operate, and the material is torn and crushed under its action. Finally, the shredded material is discharged through the discharge port, and different discharge specifications and methods can be set according to needs.

The application:

Due to its efficient crushing capacity and flexible processing capabilities, double shaft shredders are widely used in many fields. In the waste treatment and resource recycling industry, double shaft shredders can process various types of waste materials, such as home appliances, waste furniture, plastics, metals... Through processes such as crushing and separation, waste is converted into renewable resources to achieve effective recycling and utilization of resources.