Wood Shredder

Saw-dust making machines are devices powered by electric or internal combustion engines that are used to shred wood chips such as branches and cut them into chips. They are suitable for rough wood, branches, sawdust and other waste wood and can be processed into sawdust at one-time. The finished wood products are uniform in size and have less impurities. The size of the finished products can be adjusted according to the size of the built-in screen mesh and is suitable for a variety of materials. These chips can be used as compost, mulch or disposed of at recycling centers and later used in other industries such as the furniture and construction sectors.

The technical parameters:

Model | BT-6130 | BT-6145 |

Production capacity(t/h) | 2 | 5 |

Power(kw) | 23.6 | 75 |

Maximum diameter of wood branches(mm) | 130 | 250 |

Cutter roller disc diameter(mm) | 300 | 500 |

Speed(r/min) | 2600 | 2500 |

4 moving blades, 1 stationary blade | 4 moving blades, 1 stationary blade | |

Blade length(mm) | 155 | 230 |

Feed roller diameter(mm) | 280 | 500 |

Overall dimension(mm) | 2300×1300×1800 | 3200×1700×2400 |

Packing size(mm) | 2400×1400×1100 | 3350×1850×1550 |

Total weight(kg) | 980 | 2600 |

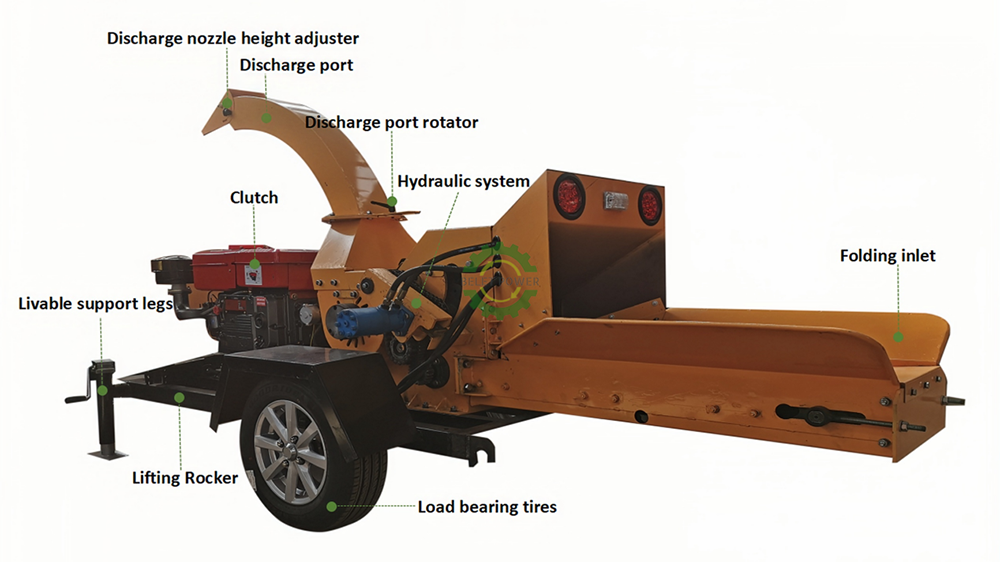

The structure:

Biomass raw materials:

Wood, branches, leaves, board, dried bamboo, tree branches, waste wood, twigs, sticks, small path wood, lath, broken veneer, wood core, sapwood...

The features:

1. The processing capacity is large.

2. 360degrees rotating outlet, the wood chips unloading spray distance is more than 3 meters, and directly loaded into the truck easily.

3. Durable high speed wheel, suitable for various road conditions.

4. The hydraulic feeding speed is uniform and the roller diameter is large. Different kinds of intelligent feeding gears control feeding speed, avoiding stuck machine and improving crushing efficiency.

5. Equipped with traction structure, durable high speed wheel and suitable for various road conditions.

6. The load-bearing force of aluminum alloy wheels is convenient lightweight tires are stable and adaptable to more complex scenarios.

7. The motor version adds control cabinet equipment for safer operation.

The advantages:

1. The effective and uniform materials can be fully and effectively crushed in the crushing chamber.

2. High output, low energy consumption, high efficiency and even discharging.

3. When the equipment is used, it has the advantages of low noise, no pollution, simple operation and convenient maintenance.

4. Reasonable structure, convenient movement, automatic feeding, safety and reliability.

Production process:

When branches enter the feed port of the crusher, they are first cut into smaller fragments by high-speed rotating knives or blades. These blades are usually mounted on rotors, and the cutting force generated by high-speed rotation shreds the branches. The cut branch fragments then enter the crushing area of the crusher, where there are usually multiple hammers or rotors that hit, tear and grind the materials at high speed. In this process, the materials are repeatedly impacted and rubbed, and gradually broken into smaller particles. In addition, the saw-dust making machine is usually equipped with a screening device to screen the crushed materials and classify particles of different sizes as needed.

In general, the working principle of saw-dust making machine is to use high-speed rotating blades and crushing devices to cut, hit, tear and grind branches, and finally break them into wood powder of uniform specifications.

The application:

This machine is widely used in wood processing, garden waste treatment and other fields. The crushed materials are widely used as the primary raw materials for biomass particles, wood-based panels, machine-made charcoal, organic fertilizers and so on, and can also be further processed into sawdust as a culture medium for edible fungi for breeding. It is also a raw material required by power plants, biomass pellet plants, and wood-based panel plants. It is also the equipment needed for landscaping work. It can operate without foundation, and the equipment can be operated when it is placed on the ground. It is driven by a single motor, which saves power and electricity.

Test the machine before shipments: