Feed Pellet Machine

Products description:

Feed pellet machine (also known as pellet feed machine or pellet feed forming machine) is widely used by farmers who breed chicken, rabbit, cow, sheep, cattle, pig, and animal husbandry. The feed pellet machine adopts a template, and the pressure roller is made of alloy steel after special treatment,so the nutrients inside the raw materials can be maintained. The length of the particles can be controlled by adjusting the cutting angle.

The parameters:

Model | Power (kw) | Designed output(kg) | Speed | Size(mm) |

120 | 3 | 20--40 | 320 | 1020×530×1120 |

125 | 3 | 40--50 | 320 | 1040×550×1140 |

150 | 4 | 75--125 | 320 | 1280×600×1250 |

180 | 7.5 | 125--175 | 320 | 1400×750×1300 |

210 | 11 | 200--250 | 320 | 1500×850×1400 |

Raw materials:

Corn, corncob, soybean meal, peanut, straw, straw powder, rice husks, grass, grain, wheat, wheat bran, seed, pine wood, bamboo, paper, coffee shell...

The features:

1. Simple structure, wide application, small floor space, low noise level, convenient use and safe operation.

2. It is easy to install and maintain and improve efficiency by extra-large input size,as well as have enough power with efficient heat dissipation.

3. Only need to add a little amount of liquid or no need at all to make powdery feed and grass meal into pellets. Thus moisture content of granule feed is basically the same moisture content before granulation, so as to be easily stored.

4. Feed of chicken, duck, fish etc guarantees higher economic benefit than mixing powdery feed.

5. Feed pellets made from dry materials are with higher hardness level, smooth surface, cooked inside and will make nutrition easily digested.

6. The formation process of pellets will make pancreatic enzyme boycott factor in grains and beans denaturized, to reduce bad effects on digestion and kill all kinds of parasite eggs and other pathogenic microorganisms and reduce all kinds of parasitic and digestive system diseases.

7. The machine can be selected according to different needs of customers:dies with different diameters.

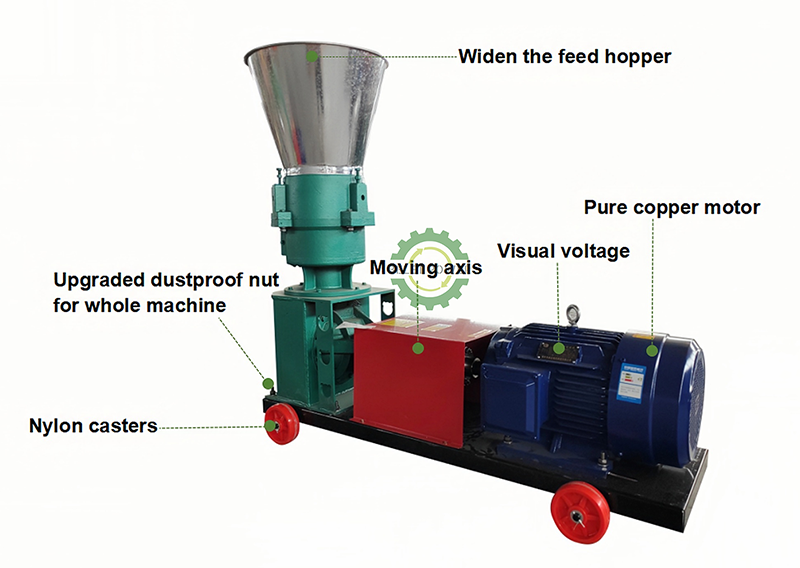

The advantages:

1. Extensive processing feed: particle length can be adjusted, thickness can be selected.

2. Upgrade grinding wheel: high-quality Ming Manganese steel material for longer service life.

3. Stable and durable: made of stainless steel, after high temperature hardening, it is more durable than ordinary steel.

4. Newly upgraded coupling operation: less transmission ratio loss and less loss.

5. Nylon pulley: will not damage and strong load.

6. Increase the outlet: there are baffles on both sides to prevent the feed from falling.

7. Widen and increase the inlet: it is convenient to put the feed ingredients that need to be made into the feed port.

The structure:

Production process:

The main shaft and flat mold are driven by friction to rotate the pressure roller. The pressure roller and the template generate high temperature, causing starch to ripen, protein to denature and solidify. Under the compression of the pressure roller, it is discharged from the mold hole, and the particles are sent out of the machine through a throwing plate.

The applications:

1. It is mainly suitable for crude fiber granulation.

corn stalks, sawdust, rice husks, cotton stalks, cottonseed husks, weeds and other crop stalks, granulation of materials with low bonding rate and difficult to form, and can also be used for low-temperature granulation of biological fertilizers, organic fertilizers, compound fertilizers, etc.

2. Feed pellet machines are widely used in large, medium and small aquaculture, grain feed processing plants, livestock farms, poultry farms, individual breeders and small and medium-sized farms, breeders or large, medium and small feed processing plants.