Vertical Ring Die Pellet Machine

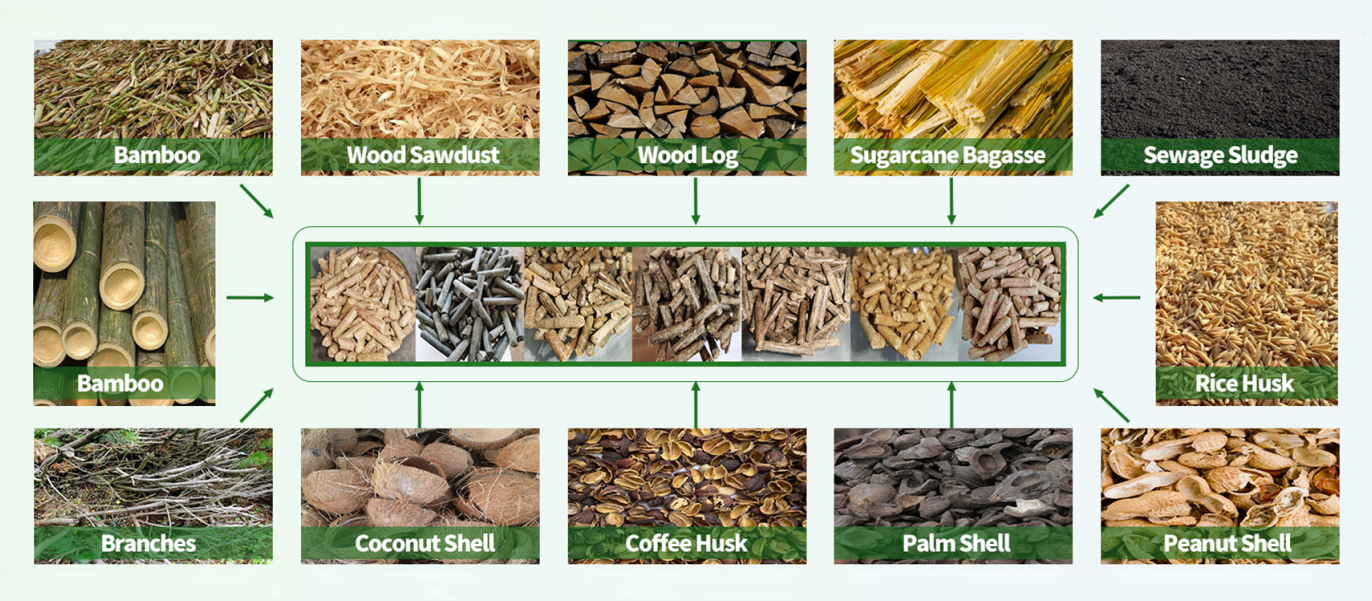

The vertical ring die pellet machine has a strong pressure and is suitable for pressing materials that are difficult to bond. Vertical ring die pellet machine is widely used in power station, wood factory, feed factory, chemical factory, becoming the ideal equipment for compression density molding with small investment, fast return and no risk. Pellet making machine can handle various materials: agricultural waste (coconut shell, palm shell, wood log & branches, sugarcane bagasse, rice husk, pine wood, etc.), residues of various kinds of wood as branches and trunks, the peels and other raw materials of various crops.

The technical parameters:

Model | LHK470 | LHK560 | LHK560-B | LHK700 | LHK850 |

Power(kw) |

55

| 110 | 132 | 160 | 220 |

Pellet diameter (mm) | 4-12 | 4-12 | 4-12 | 4-12 | 4-12 |

Pellet length (mm) | 10-40 | 10-40 | 10-40 | 10-40 | 10-40 |

Designed output(t/h) | 0.7-1 | 1-1.5 | 1.5-2 | 2.5-3 | 3-4 |

Weight (t) | 4.5 | 5.2 | 5.8 | 7.5 | 12.6 |

Pellet forming rate | 98% | 98% | 98% | 98% | 98% |

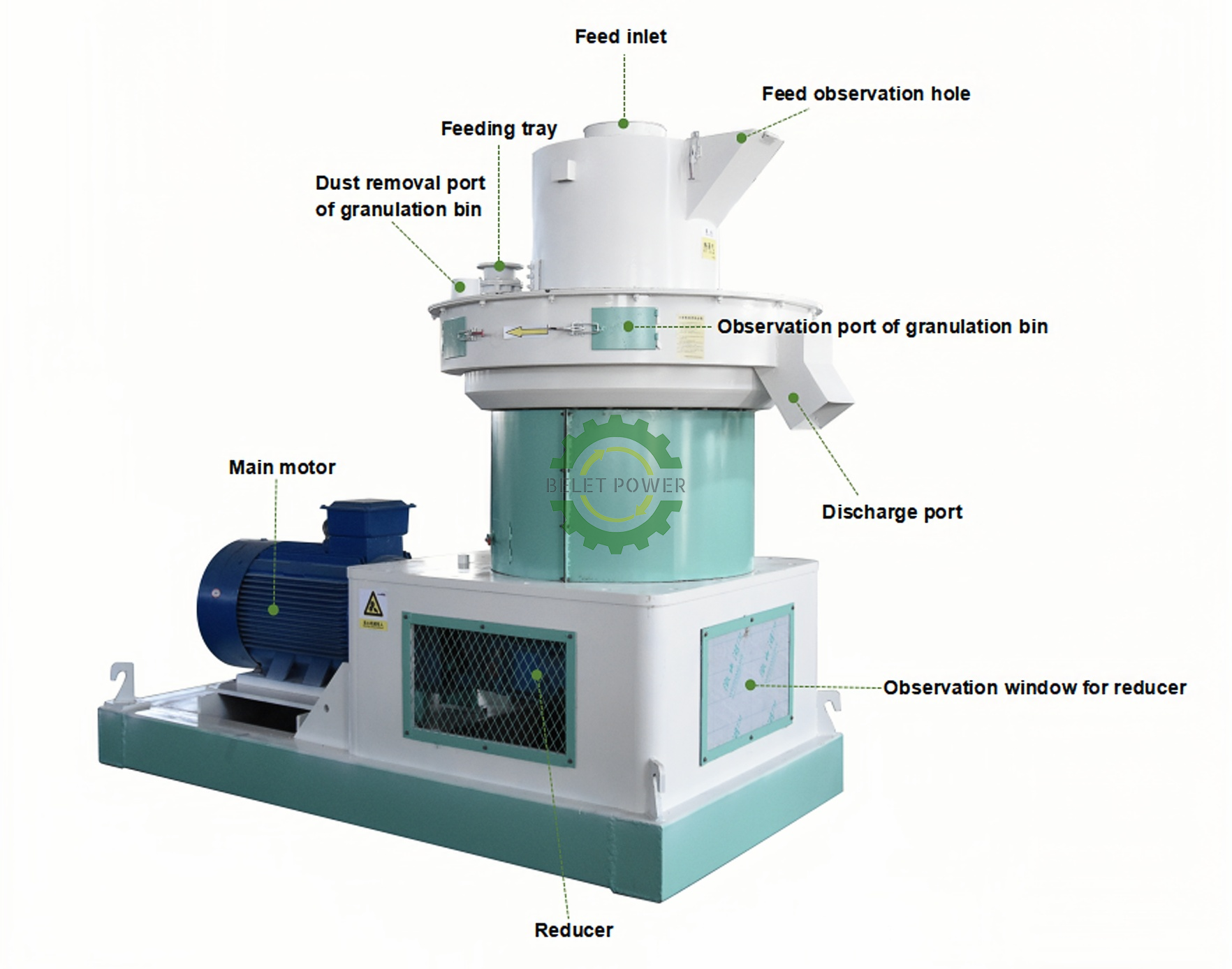

The structure:

Ring die pellet machine is generally composed of 5 parts: main motor, feeder, pellet manufacturer, regulating structure, lubrication system.

The features:

1. Vertical feed, directly in place.

2. The die is stationary, the pressure wheel is rotating, the material is centrifugal, and the die is distributed all around.

3. Two layers of abrasives, up and down dual use, cost reduction and efficiency; It can also be double used, high yield and energy saving.

4. Ring die, vertical structure, conducive to the pellet machine chamber heat dissipation and cooling.

5. Independent discharge device to ensure the formation of particles

The advantages:

1. Strong automation, stable operation, no need special care.

2. Increase discharging area, increase production capacity.

3. Roller without lock, less grease consumption, extended bearing life.

4. Heavy-duty gearbox transmission, gear strength is enhanced 5-10 times, low failure rate, strong stability.

5. Circulating gear oil lubrication, reduce grease consumption costs, protect bearings.

Biomass raw materials:

Wood chips, shavings, sawdust, corn straw, wheat straw, cotton stalk, caragana, straw, rice husk, peanut shell, palm shell, furniture factory waste, waste cloth, newspaper corn cob, branches, leaves, sawdust and other crops, solid waste (edible fungus residue, furfural residue, wine residue, etc.), can be processed biomass fuel particles, can also be processed coarse fiber feed particles.

Production process:

In the whole pellet production line, pellet machine is the crucial equipment, all other equipment associated served the pelleting and guarantee the raw material before reach the pelletizing section can meet the request of water content, size request.

The application:

The biomass wood pellets can be used as a new energy for power generation in lager power plants; can be used for fireplace, BBQ, etc.; can be used for boiler; provide comprehensive nutrition for crops; increase and renew soil organic matter.