Horizontal carbonation Furnace

Production Description

The horizontal carbonation furnace is mainly composed of a carbonation chamber, heating equipment, racks, flue gas purification system, control system, slag discharge device, feed port, discharge port, etc. In addition, there is a layer of heat insulation cotton sandwich between the outer furnace and the inner furnace. The horizontal carbonation furnace controls the temperature, time and environmental atmosphere in the carbonation chamber, and releases the moisture and volatile substances in the raw materials through a series of chemical reactions to form a stable charcoal product.

The carbonation furnace adopts a horizontal manufacturing method. The carbonation furnace is a three-layer structure with insulating materials in the middle to always maintain the temperature in the furnace.

Wood Charcoal Machine adopts advanced hot air carbonation technology, which can carbonize large logs, bamboo, branches and other materials.

Greatly improve the carbonation rate, easy operation, environmental protection and energy saving, can save a lot of energy, from the original carbonation rate of about 80% to 99%.

The technical parameters:

Voltage | Motor Customized |

Power(w) | NO/ 1.5KW |

Core Components | purification system |

Effective Volume | 2-4CBM |

Warranty | 18Months |

Weight (kg) | 2300 |

Dimension(l*w*h) | 1*1.8*1.7m |

Key Selling Points | Easy to Operate |

After-sales Service Provided | Engineers available to service machinery overseas |

Capacity | 1000KG/DAY |

Carbonization Time | 6-8 Hours |

Fuel | Biomass /coal Gas |

Usage | Natural wood charcoal making machine |

Installation | Engineer Guide |

Carbonizing rate | 99% |

Raw Materials and Finished Products

The hardwood carbonation furnace can carbonize raw materials such as waste branches, bamboo knots, bamboo tubes, fruit wood, oak, coconut shells, palm shells, etc. The quality of charcoal is not only related to temperature, but also to the humidity of raw materials. The humidity of the charcoal is too high, which will prolong the carbonation time on one hand. On the other hand, when the wood is paralyzed, a large number of harmful substances are produced. Therefore, the lower the wood humidity, the better the carbonation effect.

Working Principle

In fact, the working principle of the hardwood carbonization furnace and the vertical carbonization furnace are very similar. They all use dry distillation carbonization and airflow carbonization methods. By then heating and decomposing the wood under oxygen-free or low-oxygen conditions, the wood produces wood vinegar, wood tar, and other ingredients. Moreover, the exhaust pipe of the horizontal airflow carbonization furnace can collect the flue gas in time and deposit harmful

Feeding raw material and sealing the furnace: use the rail car to feed the raw material into the carbonization furnace and lock the furnace door, finally sealing the furnace. Preheating and drying the raw material: use the wood or other fuel heat the raw material inside the furnace, from room temperature slowly heat up to 220-250℃, this process time is about 1.2 to 2.0 hours (the specific heating-up time is mainly depend on raw material moisture content, density, diameter size etc.), discharge water inside the raw material and the air in the inner tank. Anaerobic carbonization: When the temperature inside the carbonization furnace increase to there is little yellow smoke discharged from the smoke tube (hydrogen, oxygen and other volatile substances).

Advantages

The new environmentally friendly horizontal carbonization furnace adds a flue gas recovery device on the basis of the original carbonization furnace. After the flue gas is recovered, it can be dust-free and smoke-free. The recovered flue gas can be ignited like liquefied petroleum gas for heating, cooking, and baking. Dryer use.

Best carbonization effect and shortest carbonization time. High carbonization rate, no smoking, little pollution, high efficiency. Dry distillation, the carbonization temperature can be controlled and adjusted, the highest temperature can reach 800-1000 °C. It can collect wood tar oil and exhaust gas which can be recycled.

Application

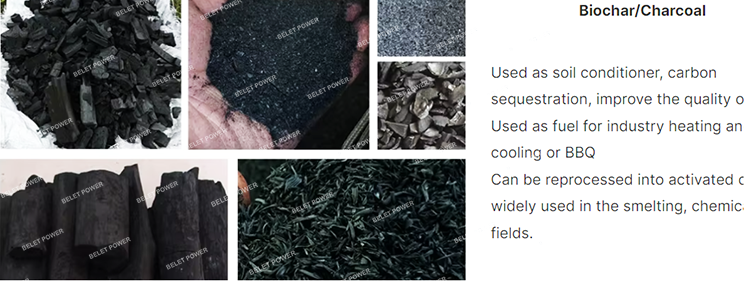

It can be used in a charcoal production line or used alone. The bamboo charcoal, coconut shell charcoal, fruit charcoal, etc. carbonized by the horizontal carbonization furnace can be directly burned for heating.

And home barbecue can use this charcoal. Therefore, the small hardwood carbonization furnace is suitable for household use. Because charcoal is environmentally friendly and has high calorific value and is renewable, it has a large demand. So it can be seen that a carbonization furnace is a good tool for making money.

During the biomass carbonization production process, tar and wood vinegar can be extracted according to customer requirements. By adding condensation equipment to the combustible gas pipeline, a mixture of tar, wood vinegar and water can be extracted. Subsequently, pure tar and wood vinegar components can be separated through physical standing or other chemical methods.