Flat Die Pellet Mill

Flat Die Pellet Mill has two types of working principles: one is the type in which roller rotates and the other one is the type in which die rotates. According to the power supply, there are 4 types of flat die pellet mills: electric pellet mill, diesel pellet mill, PTO pellet mill and gasoline pellet mill. Depending on the usage of pellets, flat die pellet mill can be divided into biomass pellet machine and animal feed pellet machine. The core components are composed of a rotating flat die and a fixed roller.

The parameters:

Model | Power (kw) | Designed output(kg) | Speed | Size(mm) |

210 | 11 | 200--250 | 320 | 1500×850×1400 |

260 | 15 | 350--500 | 380 | 1980×800×1600 |

300 | 22 | 500--800 | 380 | 2080×900×1750 |

350 | 30 | 800--1200 | 400 | 2000×860×1700 |

400 | 37 | 1200--1500 | 400 | 2200×1200×1950 |

Raw materials:

Wood shavings, wood logs, tree branch, sawdust, peanut shells, bagasse, corn straw, rice straw, wheat straw, cotton stalk, alfalfa grass, grain shells, coconut shells, palm leaves ...

The features:

1. The mold is fixed, the pressure roller rotates, and the material is evenly wound centrifugally.

2. It is powered by a high-efficiency motor, which is connected to the gearbox through a universal joint (or the motor shaft is directly connected to the gearbox).

3. The gears inside the large gearbox are large and strong, suitable for pressing hard molding materials, the machine has high pressure, works more stably, and has a long life.

4. The pellets after molding are extremely convenient for transportation and storage.

5. Its combustion performance is greatly improved, reducing human dependence on fossil energy and atmospheric emissions.

The advantages:

1. They are smaller in size and also lighter in weight as compared to other types of pellet mills and suitable for small scale production businesses.

2. Flat die pellet mills are easy to be washed, cleaned, and looked after as compared to the other types of pellet mills.

3. Pelletizing chamber can be easily observed which makes it more convenient for the workers to observe the whole process of pellet formation.

4. Flat die pellet mills are robust and strong to tolerate different materials.

5. Easy to operate and maintenance.

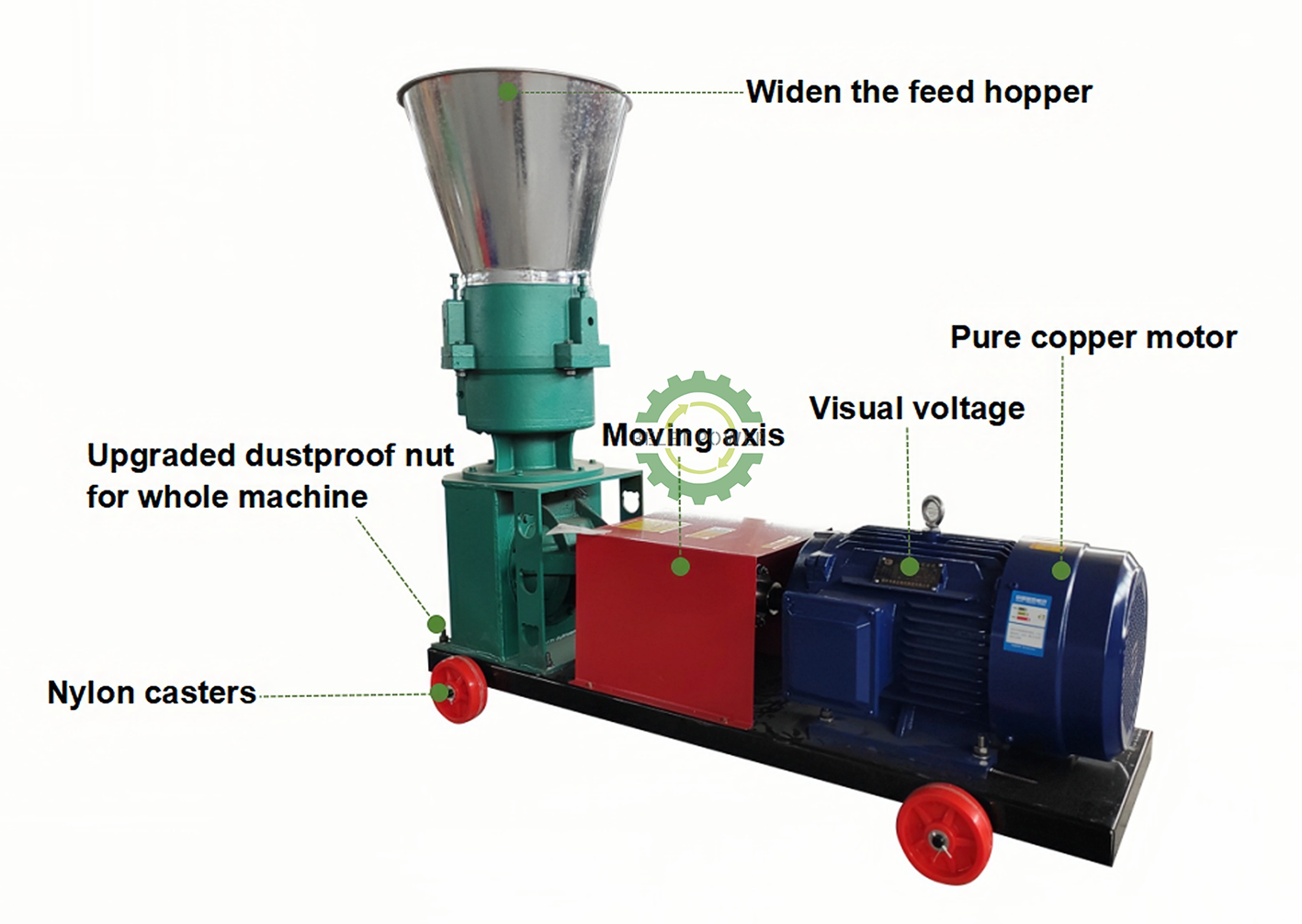

The structure:

Flat die pellet mill is mainly composed of 5 parts like press roller, flat die, feeder, gear bearings and power source.

Production process:

Flat die pellet mill is mainly composed of press roller, flat die, feeder, gear bearings and power source. Roller and flat die are used for the pelletizing process.The flat die is covered with many small holes, the selected raw material is poured from the above into the pelletizing chamber where it is compressed in between the roller and die and formed. A knife cuts the pellets coming out of the holes of the flat die and compressed or dense pellets start coming out of the machine within a few seconds. They are collected in a large container and then stored for future use.

The applications:

1. Flat die pellet mills are used to make biomass pellets.

Biomass pellet mill can be used as fuel for heating, cooking, BBQ or animal bedding, cat litter, and so on. It is widely used in farms, wood pellet production line, furniture factories, homes, and many other places to save cost or start new business.

2. Flat die pellet mills are used to make animal food pellets.

Flat die feed pellet machine is a very convenient small commercial feed pellet mill for farmers who cultivate cattle or livestock like rabbit, duck, pig, cow, chicken, sheep, and others.