Rotary Dryer Machine

Drum dryer machine is the main body slightly tilted and can be in a specific range of adjustable rotational speed of the cylinder, the wet material is fed into the cylinder by the feeding machine, the cylinder is evenly distributed in the cylinder under the turnover of the platen, the material is evenly distributed in the dryer and dispersed and through the cylinder through the full contact of hot air (concurrent or countercurrent) to accelerate the drying of the heat transfer, mass transfer, so as to achieve the purpose of drying.

The technical parameters:

Model | Cylinder diameter (mm) | Cylinder length (mm) | Effective volume (m³) | Cylinder speed (r/min) | Inlet air temperature (°) | Production efficiency (t/h) | Power (kw) | Weight (t) |

BT0660 | 600 | 6000 | 1.7 | 4-10 | <750 | 0.5-1.8 | 3 | 2.9 |

BT0880 | 800 | 8000 | 4.0 | 4-10 | <750 | 0.8-2.3 | 4 | 3.5 |

BT0810 | 800 | 10000 | 5.0 | 4-10 | <750 | 0.8-2.8 | 4 | 4.5 |

BT1010 | 1000 | 10000 | 7.85 | 4-10 | <750 | 2-5 | 5.5 | 5.6 |

BT1212 | 1200 | 12000 | 13.56 | 4-10 | <750 | 4-10 | 11 | 14.8 |

BT1512 | 1500 | 12000 | 21.2 | 4-10 | <750 | 8-15 | 18.5 | 17.8 |

BT1818 | 1800 | 18000 | 45.78 | 2-6 | <750 | 10-23 | 22 | 31 |

BT2018 | 2000 | 18000 | 56.52 | 2-6 | <750 | 15-26 | 30 | 43 |

BT2218 | 2200 | 18000 | 68.4 | 1.5-6 | <750 | 20-32 | 37 | 52 |

BT2418 | 2400 | 18000 | 81.4 | 1.5-6 | <750 | 25-38 | 55 | 60 |

BT2820 | 2800 | 20000 | 123 | 1.5-6 | <750 | 35-50 | 75 | 72 |

BT3025 | 3000 | 25000 | 176.6 | 1.5-6 | <750 | 40-65 | 90 | 104.9 |

BT3225 | 3200 | 25000 | 200.1 | 1.5-6 | <750 | 75-105 | 132 | 166 |

BT3625 | 3600 | 25000 | 254.34 | 1.5-6 | <750 | 95-160 | 160 | 188 |

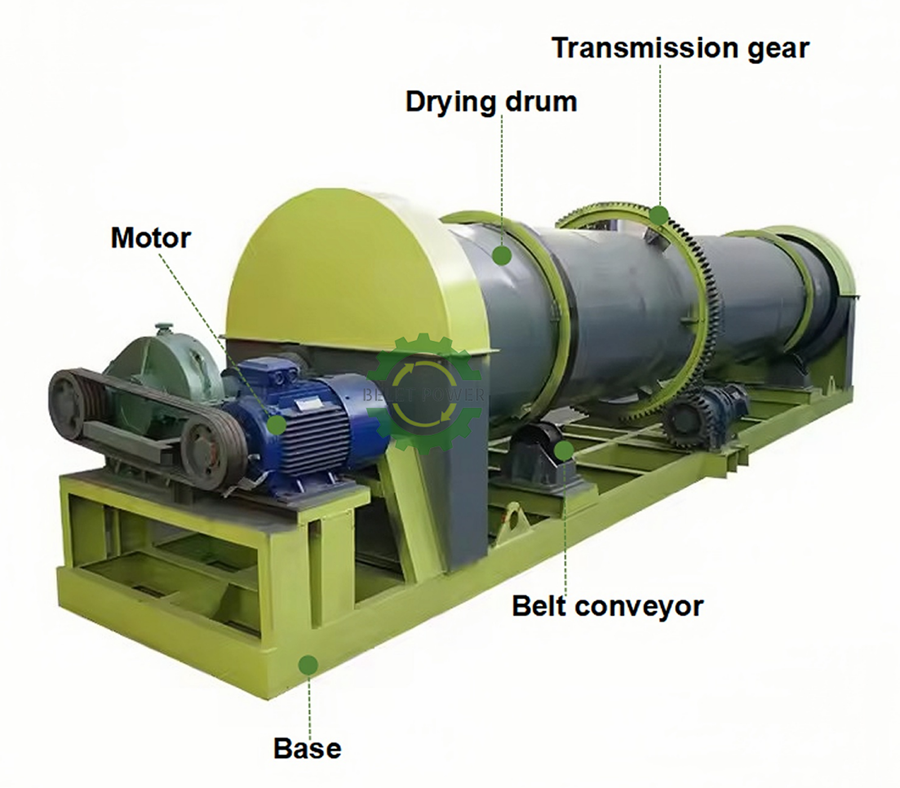

The structure:

The Drum dryer machine is mainly composed of a drum device, front and rear supporting roller devices, a feeding and discharging device, a transmission device and a gear cover.

Biomass raw materials:

Facturing sand, glass sand, iron powder, ouartz sand, titanium powder, machine-made sand, slag, stone powder, river sand, clay, sludge, slurry, gypsm powder, white bole, lepidolite, animal waste, saw dust, crop waste

The features:

1. Simple and reliable operation, a wide range of application, good drying effect.

2. The rotary dryer with high mechanization, especially strong production capability and continuous operation.

3. The rotary dryer is designed with excellent and simple structure, the steady operating process under the resistance of the drum, which is easy to operate.

4. It meets different objectives of customers with High Performance in little malfunction, low maintenance cost, and power consumption.

The advantages:

The drum dryer machine has large processing capacity, low fuel consumption and low drying cost. The dryer is characterised by high temperature resistance, capable of using high temperature hot air to dry materials quickly, strong overload resistance, smooth cylinder operation and high reliability.

1. High wear resistance

The drum of the dryer is made of steel, which is more wear-resistant than other materials and has a longer average service life.

2. Strong cylinder

The welding material of the cylinder body adopts the similar welding rod with the material of the cylinder body.It makes the cylinder more stable and firm.Effectively cantrol the deformation and cracking problem.

3. Long-lasting work

The dryer gear has high toughness and strength,which can keep the gear working normally and persistently.And the processing precision is high and durable.

4. Convenient operation

Adjustment of the pallet wheel can be done only by moving the cylinder.As the adjustment of the carrier wheel needs to add lubricating oil to ease the friction, thus playing a role in reducing the surface friction.

Production process:

The machine adopts a flow and sealed drying process:

1. The wet material containing moisture enters the dryer.

2. Evenly dispersed and fully contacted with hot air in the rolling dryer under the flipping of the

lifting plate which accelerates the drying heat transfer.

3. The material is discharged into the finished product at the discharge head.

The application:

Drum dryer (rotary dryer), also known as dryer for short, is a dryer that processes large amounts of materials. Due to its reliable operation, flexible operation, strong adaptability, and large processing capacity, it is widely used in metallurgy, building materials, food, light industry, chemical industry, coal, medicine, and mining industries.