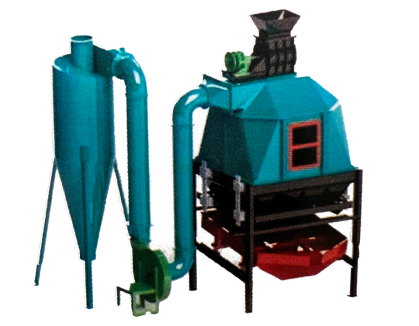

Pellet Cooler

The pellet cooler is one of the key machine in feed pellet production line. The cooler is mainly used for cooling of hot pellet feed, about 3-5 degress higher than room temperature, which is in the feed pelleting section. And it is capable of lowering to a safety moisture content. With special coercive discharging system, it can be used in all kinds of raw material. The unique structure of the cooling system, relative movement between cooling air and materials, make the pellet forward step by step to cool. The cooled pellets not only can improve the pellet firmness but also can prevent from going mouldy, that it is good for the transportation and storage of pellet feed.

The technical parameters:

Model | Power(kw) | Pellet types | Productivity(t/h) |

BT1.5 | 1.1 | 1-2 | |

BT2.5 | 2.2 | Biomass, feed, fertilizer pellets | 2-3 |

BT4 | 2.2 | Biomass, feed, fertilizer pellets | 4-6 |

BT6 | 3 | Biomass, feed, fertilizer pellets | 7-10 |

BT8 | 3 | Biomass, feed, fertilizer pellets | 10-15 |

BT10 | 3 | Biomass, feed, fertilizer pellets | 15-20 |

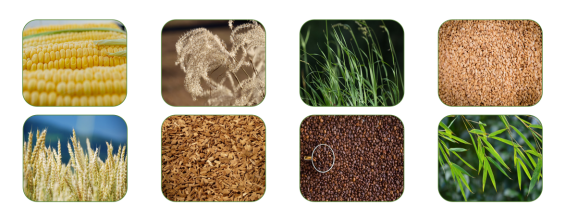

Biomass raw materials:

Corn, corncob, soybean meal, peanut, straw, straw powder, rice husks, grass, grain, wheat, wheat bran, seed, pine wood, bamboo, paper, coffee shell, wood shavings, wood logs, tree branch, sawdust, peanut shells, bagasse, corn straw, rice straw, wheat straw, cotton stalk, alfalfa grass, grain shells, coconut shells, palm leaves, plastic, paper...

The features:

1. The pellet cooler working principle is adopted to cool the pellets with high temperature and moisture.Hot air touches hot pellets and cool air touches cool pellets so as to avoid the pellet surface crack caused by sudden cooling produced by direct touching between cool air and hot pellets.

2. The temperature of the pellet after cooling is not higher 3-5 ℃ than room temperature, and the cooling times is not less than 6-10mins.

3. The top of cooler is made of stainless steel, resulting in high corrosion-resistance and long service life.

4. It adopts unique slide valve discharge mechanism as well as works stably and discharging smoothly.

5. It has convenient adjustment and high automatically degree, which is suitable for cooling of any granular products.

6. Multiple pressure reducing plate is equipped with discharging device, can lighten the working load of discharging device, reduce the deformation and prolong the working life.

7. The access door is adjustable discharge opening, it is applicable to the treatment of conventional pellet feed.

The advantages:

1. Materials are feed from the top to the bottom, and the cold air is from the bottom, which realizes effective and fully cooling.

2. Airlock feeder is used for feeding, with large air volume and good cooling effect.

3. The octagon cooling bin has eliminated dead cooling corner, which is beneficial to the cooling treatment of materials.

4. The reciprocating slide valve discharging mechanism is stable and reliable in working process, which guarantees less residue.

5. The gearbox drives eccentric shaft as transmission gear, smooth and reliable running, no material deposit, lower noise, easy to install and maintain.

6. The unique discharging method is adopted, which relies on the reciprocating motion of the movable frame to change its relative position with the fixed frame, so that the bottom of the entire cooler is discharged in the form of lines and gaps, and the discharging is uniform.

Production process:

The high-temperature and high-humidity pellets from the pellet machine are evenly stacked in the cooling box through the rotary air-closed feeder and the diamond cone bulk feeder.The cold air enters the cooler from the bottom of the slide valve discharge mechanism under the cooling box and the gap on the top of the collecting hopper.It vertically passes through the material layer to exchange heat with the hot and humid pellets, and is then sucked out through the suction system, so that the pellets can be cooled.The cooling time is controlled by the position of the upper and lower level gauges.When the pellet layer reaches the upper material level, the motor is turned on to start discharging.When the pellet layer is lower than the lower material level, the motor stops and the discharging stops.After the motor stops, the relative position between the movable frame and the fixed frame in the slide valve discharge mechanism is controlled by the travel switch through the brake motor, so that no leakage can be ensured after stopping the discharge.The slide valve discharge mechanism is installed at the bottom of the box.The deceleration brake motor makes the movable frame reciprocate through the eccentric mechanism, changing the relative position between the movable frame and the fixed frame, so that the pellets are discharged from the box and discharged from the collecting hopper.

The application:

The pellet cooler is mainly used in the cooling system of feed pellet production line or biomass wood pellets production line.