Hammer Sawdust Making Machine

Multi-purpose hammer saw-dust making machine is an essential equipment for the early production of many industries, especially the pharmaceutical, feed, food, coating and chemical industries. It has wide versatility, can adjust the crushing fineness, has the advantages of high production efficiency, low energy consumption, safe use and convenient maintenance, so it has been favored by all walks of life.

The crushing effect of hammer mill is mainly evaluated by three indicators: crushing fineness, crushing output per unit time and unit energy consumption of crushing process. These indicators depend on the physical properties of the crushed material, the structure of the crusher, the shape of the crushing chamber, the number, thickness and linear speed of the hammers, the shape and aperture of the screen holes, the gap between the hammers and the screen surface.

The technical parameters:

Model | BT-600 | BT-800 | BT-1000 | BT-1300 | BT-1500 |

Feed port size(mm) | 600*300 | 800*350 | 1000*350 | 1300*400 | 1500*450 |

Hammer thickness(mm) | 80-12 | 80-12 | 80-12 | 80-12 | 80-12 |

Number of hammers | 40-50 | 40-60 | 40-70 | 54-90 | 60-100 |

Rotor speed(r/min) | 2600 | 2400 | 2200 | 2000 | 1800 |

Motor power(kw) | 30-37 | 45-55 | 75-90 | 90-110 | 110-150 |

Production efficiency(t/h) | 0.8-1.5 | 1.5-2.0 | 2.0-2.5 | 2.5-4.0 | 3.5-5.0 |

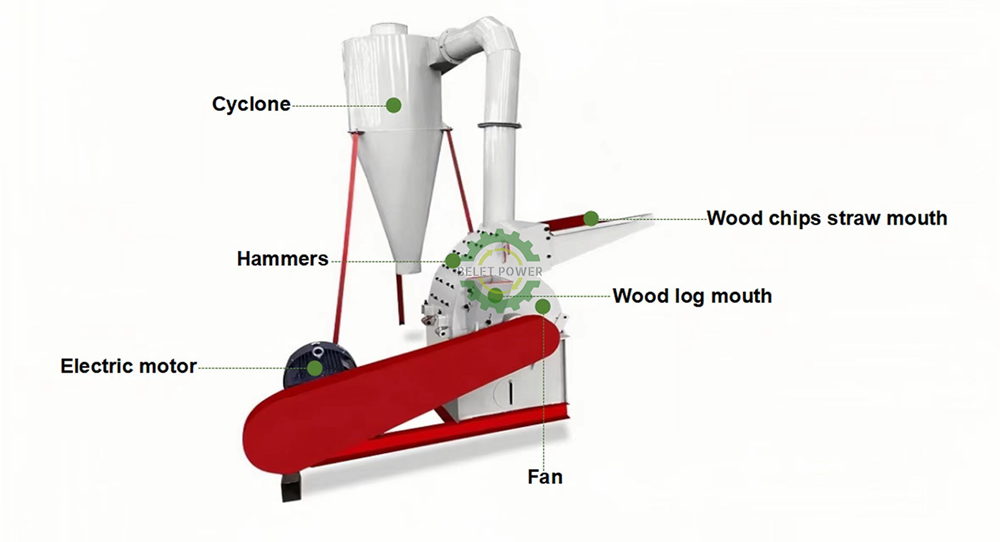

The structure:

The saw dust making machine has a bearing table, a fixed knife table, a screen, and a screen frame. The characteristics are that the bearing table and the fixed knife table are cast on the same plane outside the reserved hole of the lower casing shaft, and the screen frame is fixed in the lower casing by screws to form a stepped shape, and its circumference is an ellipse.

Biomass raw materials:

Wood pieces, straw, grass, stalk, tree branches, waste cardboard, bamboo, wood scrap, corn stalk, peanut shell, wheat stalk, wood fuel, cotton stalk, biomass shell, corn, wheat, rice husk, corn straw, fermented cow dung, wood shavings, cotton straw, eugenia, mixed wood, redwood, white pine, camphor pine, cat litter...

The features:

1. This kind of grain grinding machine is widely used in swine farm, feed factory.

2. The raw materials can be crushed into straw particles, whose diameter is 3-5mm.

3. The durable crusher works with high efficiency and gains more good reputation from European users.

4. Even crushing function of multi-cavities which is suitable to crush hard materials.

5. Reasonable design of leveling plate making the finished material finer and cubic-shaped without internal cracks.

6. Low and big feed opening make the production line easy to arrange and increase the size of feeding material.

7. New anti-abrasive material which prolong service life of impact hammers, impact plate and liner.

The advantages:

1. High production capacity: this machine has a production capacity of 600-800kg/h, making it suitable for large-scale production requirements, such as in food & beverage factories and shops.

2. Multifunctional design: the machine is designed to be multifunctional, allowing users to grind various grains, including wheat, cassava, and corn, into super fine flour.

3. Durable and long-lasting: with a two-year warranty and two-year warranty on core components, this machine is built to last and requires minimal maintenance, as per user input.

4. Easy to operate: the machine is easy to operate, with an adjustable fine powder size feature, allowing users to achieve the desired consistency for their products.

5. Comprehensive support: we provide video outgoing-inspection, machinery test report, and online guidance for after-warranty service, ensuring a smooth and hassle-free experience for users.

Production process:

Hammer mills mainly rely on impact to crush materials. When materials enter the hammer mill, they are crushed by the impact of the high-speed rotating hammers. The crushed materials obtain kinetic energy from the hammers of the hammer mill and rush to the baffles and screen bars in the frame at high speed. At the same time, the materials collide with each other and are crushed multiple times. Materials smaller than the gap between the screen bars are discharged from the gap. Some larger materials are crushed again by the impact, grinding, and extrusion of the hammers on the screen bars. The materials are squeezed out of the gap by the hammers of the hammer mill. Thus, products of the required particle size are obtained.

The application:

It is suitable for fine crushing of medium-hard and brittle materials in industries such as mining, cement, coal, metallurgy, building materials, highways, and combustion. Meawhile,hammer mill is used to crush various medium-hard and weakly abrasive materials.The crushed materials are coal, salt, white ash, gypsum, bricks and tiles, limestone... It is also used to crush wood and paper with strong fiber structure, elasticity and toughness, or crush asbestos cement waste to recover asbestos fibers. The equipment can adjust the grate gap according to user requirements and change the discharge particle size to meet the different needs of different users.