Disc Wood Chipper

Disc wood chipper is a special equipment for making high quality wood chips. It is not only able to cut log, small diameter wood and others into high-quality industrial wood chip which has the same length, the neat incision and the uniform thickness, but also can cut lamina, plank and others. So it is suitable for paper mill, particleboard factory, fiberboard factory and wood chip production base. It is the necessary wood processing equipment for small and medium-sized enterprises and individual household.

The technical parameters:

Model | Blade speed (r/min) | Numbers of blades | Discharge port size (mm) | Cutter diameter (mm) | Feed diameter (mm) | Production capacity (t/h) | Power(kw) |

38 | 1000 | 4 | 368*375 | 978 | 229 | 4-6 | 75 |

48 | 900 | 4,6,8 | 457*527 | 1219 | 279 | 8-10 | 110 |

58 | 720 | 4,6,8 | 559*660 | 1473 | 381 | 10-15 | 132 |

66 | 600 | 4,6,8 | 635*711 | 1676 | 445 | 15-20 | 160 |

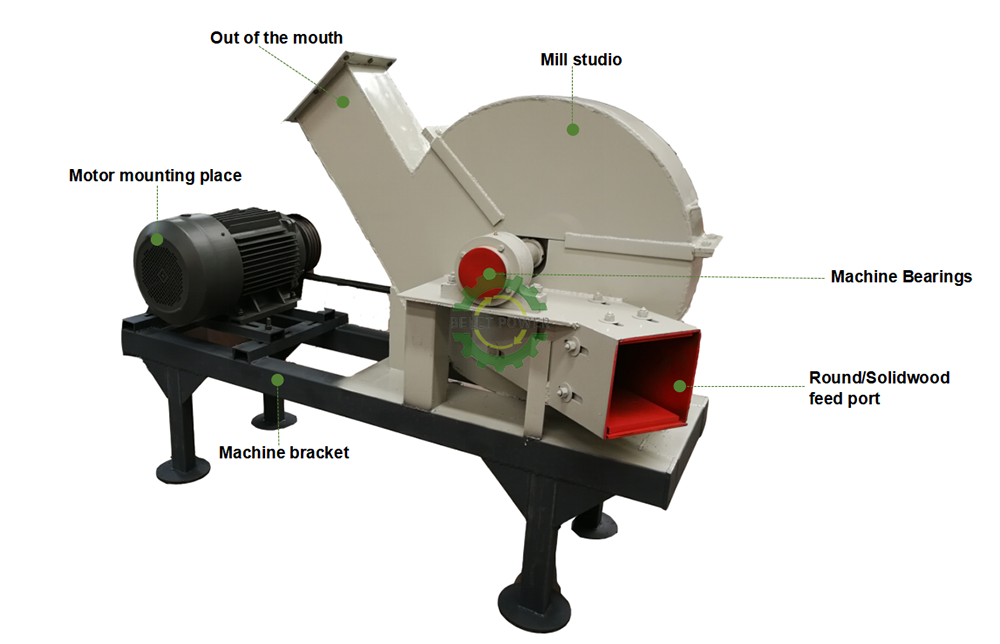

The structure:

The disc wood chipper is mainly made up of cutter, blade, bearing base, bearing box, bearing, belt, pulley, motor or diesel engine, shaft, housing and other important parts.

Biomass raw materials:

Log, small diameter wood, lamina, plank, wood sticks, tree branches, waste wood material, bamboo, bamboo pole, corn stalks, batten, bark, corn straw, leftover material...

The features:

1. Disc wood chipper can adjust the cutting blade and produce different specifications and thickness of wood chips.

2. The length of wood chip can be adjusted within a specified range in order to adapt to the different requirements of wood chip length in paper-making, fiberboard and particleboard industries.

3. Diesel engine is efficiently mute, powerful and durable. It can stable perform.

4. Widening of the feeding port for more convenient feeding can increase feed inlet.

5. Double bearing weighting built in imported bearings makes spindle bearing more firm.

6. The cutter head has sharp blades to improve production efficiency.

The advantages:

1. The disc wood chipper has a compact and reasonable structure, is easy to operate, has a large production capacity, a high rate of qualified wood chips, and low energy consumption. It is the ideal equipment for producing high-quality wood chips.

2. The disc wood chipper has low energy consumption per unit of wood chip output, high cost performance, helps to reduce production costs, and conforms to the concept of green production.

3. The disc wood chipper is cheap, it can reduce noise and the wear of the cutter.

4. It has excellent product quality: the cut wood chips have stable quality, uniform length and thickness, meeting the processing requirements of different industries.

5. The equipment adopts advanced safety protection measures to ensure safety and reliability during operation.

Production process

The disc wood chipper uses the cutting principle of the cutter disc to start the motor or diesel engine, and the belt transmission drives the cutter disc on the main shaft and the blade installed on the cutter disc to rotate repeatedly. The wood is fed in from the feed port, and when the wood contacts the cutting blade, it is cut as the cutting disc rotates at high speed, and the cut wood chips are sent out in the cutting chamber by the high-speed steam flow generated by the fan blades on the cutting disc.

The application:

1. Wood processing industry

(1) It is used to prepare industrial wood chips: disc wood chippers are mainly used to cut logs, small-diameter wood, wood, boards into high-quality industrial wood chips with uniform length, smooth cuts and uniform thickness. These wood chips are widely used in paper mills, particleboard mills, fiberboard mills and wood chip production bases, and are important raw materials in the production process of these industries.

(2) It is used to deal with waste wood: in the process of wood processing, a large amount of waste boards, scraps will be generated. Disc chippers can effectively process these wastes and convert them into useful wood chips, thus realizing the recycling of resources and improving the utilization rate of wood.

(3) Paper products industry

Wood chips produced by disc wood chippers are one of the important raw materials for the paper industry. By cutting logs and other wood into wood chips, they can be further processed into pulp for the production of various paper products such as paper and cardboard. Therefore, disc wood chippers play an indispensable role in the paper products industry.

(4) Other industrial fields

In addition to the wood processing and paper products industries, disc wood chippers can also be used in other industrial fields that require wood chips as raw materials. For example, in the field of biomass energy, wood chips can be used as biomass fuel; in the rubber products, plastic products and other industries, wood chips can also be used as fillers or reinforcing materials.