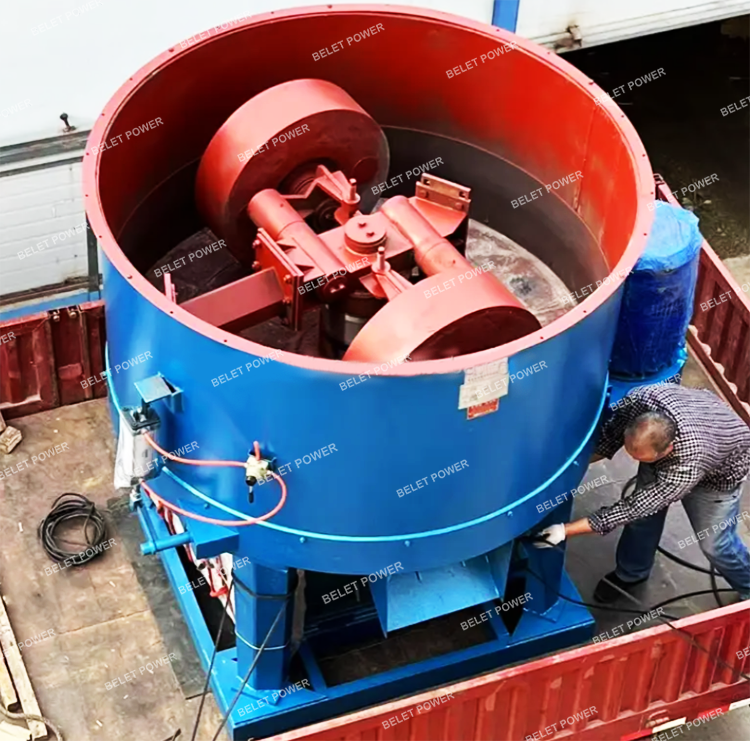

Wheel Grinder

Product Description

Wheel grinder mixer is mainly composed of the grinding wheel, grinding disk, and so on. The height of wheel can be automatically adjusted, when have a large or hard material, the rolling wheel can automatically rise, over the hard material, due to its own gravity and automatically fall. The grinding wheel and rotating shaft is connected through the crank. Motor drive speed reducer, In the process of rotation, rely on the weight of the wheel the material is mixed, At the same time, the rotation of the wheel is affected by the friction force. After the material is stirred evenly, open the discharging device, Material is discharged from the scraper to the discharge port.

Working Principle

After the machine works, the wheel will run continuously in its pot, adding charcoal or coal powder into the pot of the charcoal wheel mixer with water and briquette binder for grinding. During this process, water can be fed in for mixing to reach a certain moisture level for briquette making. Until the material is ground and mixed evenly, the discharge hole can be opened to get all the material inside the charcoal wheel roller.

Features and Advantages

1. This series equipment is mainly used for noodle sand, single wet sand, core sand and self-hardening sand.

2. Rotary roller and scraper together, high efficiency and good quality.

3. Lubrication to ensure that the machine is the best lubrication.

4. Surfacing tungsten carbide scraper, longer consumable life.

5.Alloy steel gears, low noise, long life.

6. Reliable transmission lubrication system to strengthen the system to ensure that machine operating rate of 100%.

7. Rotary discharge gate, the complete elimination of leakage of sand.

Main specifications and technical parameters

Model | Drum Diameter(mm) | Wheel Size(mm) | Capacity(t/h) | Spindle speed(r/min) | Power(kw) | Weight(t) |

WG-110 | 1000 | 420*130 | 1-2.2 | 44 | 4 | 0.92 |

WG-112 | 1450 | 590*117 | 2-4 | 34.7 | 7.5 | 1.6 |

WG-114 | 1850 | 750*240 | 6-10 | 34 | 15 | 3.5 |

WG1120 | 2200 | 800*260 | 10-15 | 30 | 37 | 5.6 |

Detailed Images

1. High production efficiency: wheel rolling is adopted, and the raw material is rolled and mixed repeatedly, so that the raw material is mixed more fully and the bonding degree of the raw material is improved.

2. Automatic setting, using gas control switch

3. Grinding machine structure is simple, easy to manufacture and maintenance, feed size requirements are not too strict.

4. There is no sieve on the board, and the lighter is polished. There is a specially designed unloading mechanism to ensure successful feeding.

5. In the mixing process, it not only has crushing and extrusion effect, but also can better remove the gap between the material particles, so that the raw material particles can be better moist and full;