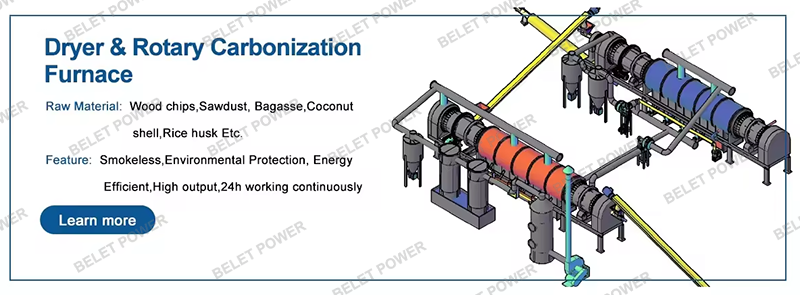

Rotary Dryer

Product Introduction:

The self-made combustible gas is used as the heating source, and the drying is divided into two parts: the drum part and the serpentine tube part. The drum part has two layers: the inner drum and the outer insulation. The inner drum is equipped with three inner spiral blades, which can make the drying materials move evenly, which is called frying heating. The serpentine tube part uses the heat source for the second time, and uses the negative pressure exhaust of the induced draft fan to extract and press the drying materials into the spiral device for separation to achieve the drying effect. The drum dryer can successfully dry raw materials with a moisture content of 35% at one time. It saves 75% of electricity and greatly reduces the drying cost. The gas source of the dryer comes from the cannibalization kiln, and the methane gas produced by the cannibalization kiln is used by the dryer.

Product Usage:

The rotary dryer is a product specially designed for drying wood chips and sawdust. The equipment integrates drying, cooling and drying in one. It is more energy-efficient than ordinary dryers and can save energy and drying costs to the maximum extent. It is mainly suitable for drying large particles and high specific gravity materials such as ore powder, coal slime, coal powder, etc. in industries such as sawdust, distiller's grains, and rice husks.

Working Principle:

The raw materials enter the sawdust dryer drum through the transmission system, are evenly distributed in the drum through the lifting plate device, and then fully contact with the hot air to accelerate the drying of hot air and mass transfer. During the drying process, under the action of the copying plate and the heat treatment of the sawdust dryer, the raw materials are dried well and meet the drying requirements. Finally, the dried raw materials are unloaded from the discharge port of the sawdust dryer.

The material enters the inner layer of the rotary drum from the feeding device to achieve downstream drying. The material is continuously picked up and scattered under the inner layer of the copy plate to achieve heat exchange in a spiral manner. The material moves to the other end of the inner layer to enter in the middle layer, counter current drying is carried out. The material is continuously raised in the middle layer, showing a two-step forward and one-step travel mode. The material in the middle layer not only fully absorbs the heat emitted by the inner drum, but also absorbs the heat of the middle drum, and at the same time extends after the drying time, the material reaches the best dry state here.

The material travels to the other end of the middle layer and falls into the outer layer. The material travels in the outer drum in a rectangular multi-loop manner. The material that achieves the drying effect quickly travels out of the drum under the action of hot air, and the wet material that does not achieve the drying effect is caused by its own weight. Cannot move fast, the material is fully dried in this rectangular copy board, thus achieving the purpose of drying.

Product advantages

1. PLC smart control & high atomicity. The performance of the rotary dryer and moisture content of dry materials is

automatically controlled in stable states.

2. High heat efficiency. The design of multiple circumferential flight combinations and flow rate adjustment devices ensures the control of the drying period and temperature distribution. The effect of insulation is as high as 70% and raises heat efficiency by 20%.

3. Four-wheel drive, more steady and stable.

4. Save 50% space compared with traditional dryers and reduce 50% civil investment.

5. Convenient variable frequency control systems. The customer could change the material flow rate and product moisture based on their needs.

6. Environmental and safe. Modular configuration of dust collection and purification systems

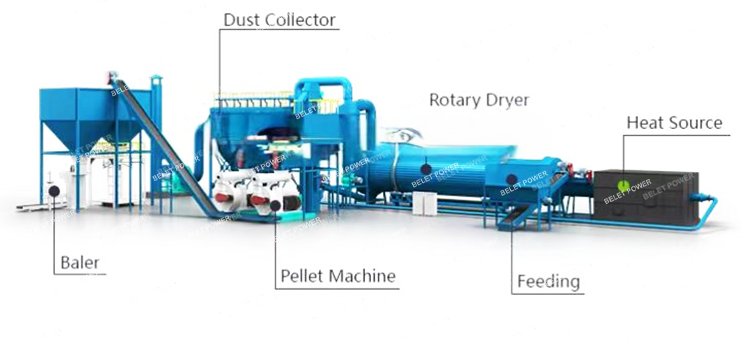

Production Structure

Applicable Materials

It is suitable for many industries:

Aquaculture, agriculture, industry, and construction. Stainless steel material can be customized.