Air Flow Dryer

Product Introduction

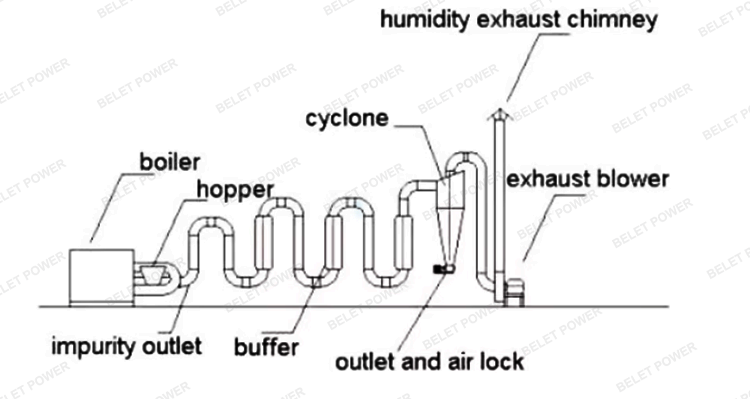

This dryer is suitable for drying materials with 30-60% moisture. The wet materials are input into the hopper. The dryer is equipped with two fuel boilers, inlet, steel pipe, exhaust blower (fan), airlock and cyclone separator. The wet materials are input into the hopper.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Molding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Molding Machine PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

This is our horizontal carbonization furnace stove kiln it can make the raw materials such as man-made wood briquettes , wood branches, bamboo, jute stick and ant type of the stick shape biomass materials into charcoal directly.

Other requirements

The fuel boiler produces hot air, which is mixed with the wet materials and then quickly sucked into the pipe by the exhaust blower (fan). The hot air then flows through the bent pipe and buffer chamber (drying chamber) of the dryer, thereby drying the wet materials, and the dried materials are discharged from the outlet through the airlock. This wood dryer can reduce the moisture to 8-12% at a time, with the advantages of low cost consumption and high efficiency.

Main Parameters:

Model | Single Furnace | Two Furnaces | Three Furnaces | ||||

HJ-A | HJ-B | HJ-C | HJ-D | HJ-E | HJ-F | HJ-G | |

Power | 4kw 1 motor | 7.5+ 1.5+ 0.75kw 3motors | 11+ 1.5 0.75kw 3motors | 7.5+ 1.5kw 2motors | 11+ 1.5+ 0.75kw 3motors | 15+ 1.5+ 0.75kw 3motors | 15+ 1.5+ 0.75kw 3motors |

Capacity(kw/h) | 300 | 600 | 800 | 400 | 1000 | 1100 | 1300-1500 |

Feed diameter(mm) | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 |

Operating temperature | Stove 300℃/ Pipes 180-200℃ | ||||||

Wood waste consumption(kg/h) | 10-15 | 15-20 | 20-25 | 25-30 | 25-30 | 35-40 | 40-45 |

Weight(kg) | 920 | 2110 | 2110 | 1400 | 2850 | 2850 | 3880 |

Overall Size(m) | 2.44*1.23*1.9 | 2.45*1.72*1.91 | 2.45*1.72*1.91 | 2.44*1.23*1.9 | 2.45*1.72*1.91 | 2.45*1.72*1.91 | 1.23*1.23*1.73 |

1.45*1.42*1.4 | 1.45*1.42*1.41 | 1.4*1.3*1.4 | 1.23*1.24*1.7 | 1.23*1.24*1.7 | 1.23*1.24*1.73 | ||

1.42*1.42*1.41 | 1.42*1.42*1.41 | 1.42*1.42*1.41 | |||||

2.44*1.72*1.91 | |||||||

Our Advantages

1. Low electricity consumption---The machine use 7.5 kW electric motor.

2. Supply customize service. Like mound.

3. We will Test the machine before Shipping and Packing for you

4. We provide perfect after-sales service, operations manual and maintained.

5. We are Source Machinery plant with more than 31 years’ experience.

The nature of the air dryer:

1-After the installation is complete, turn on the fan, check the direction of the fan rotation and whether the suction port is normal.

2- Check the flange interface to see if it leaks.

3- Bundle the bags that are open at both ends at the lower opening of the separator.

4- Add the material to be dried at the feeding port, and remove the large particles before drying, which is beneficial to increase the drying speed.

5-Add fuel to the furnace to ignite and turn on the fan. When the temperature at the wind outlet is as high as 150 °C, the material is cut off and dried.

6- Remove large pieces of material from the slag discharge port in time to facilitate feeding.

Scope of Application

Air Flow Dryer can be used to dry biomass materials (sawdust, crop stalks, leaves, grassed agricultural products (corn straw, soybean straw, cotton stalks, wheat straw, etc.), chemical products (such as fertilizer, metal powder, sugar), mining industry products (ore, sand, clay, etc.)