Corn Sheller Thresher

Product Introduction

Corn threshers thresh dried corn ears. Most are axial-flow drum-type, but some are vertical threshing disc-type. They have been popular with farmers for years due to their high production efficiency, excellent threshing quality, ease of operation, simple structure, durability, reliability, and convenient maintenance.

A corn thresher primarily consists of a drum, concave plates, a screen, a fan, a feed hopper, a kernel slide, and a spiral guide. It utilizes an axial-flow threshing mechanism with tangential feeding of the cob shaft at the end of the shaft. The process begins as corn ears enter the drum through the feed hopper. The impact of the high-speed rotating drum and the interaction between the cob, drum, and concave plates threshes the corn. The threshed kernels and fine impurities mostly pass through the concave plate holes and are cleaned by the fan. Light impurities are blown out through the impurity discharge port, and the kernels slide out of the machine via the kernel slide. The cob moves backward along the axis of the drum and is discharged out of the machine through the outlet at the end of the shaft through the surface of the vibrating screen. Some of the grains entrained in the cob leak through the screen holes and enter the grain slide and slide out of the machine.

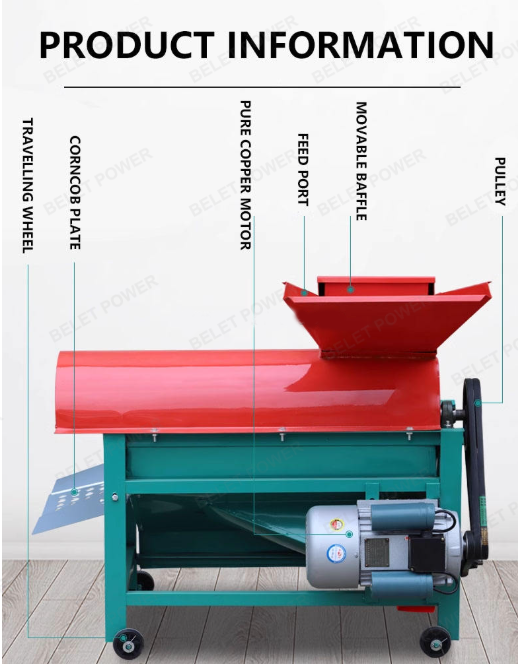

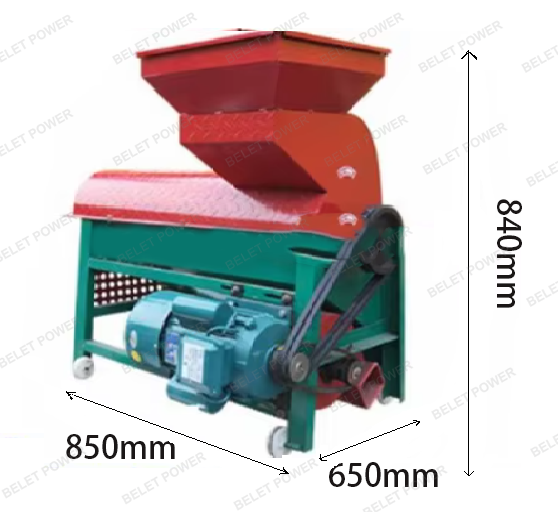

Product Structure

The main structure of the corn thresher is mainly composed of a frame, a feed port, a threshing device, a screen, an engine (electric motor, gasoline engine, diesel engine) wheel, a corn kernel outlet, a corn cob outlet, and the corn thresher has a beautiful appearance and a long service life. It is a good helper for household corn threshers.

Product Advantages

1. The corn thresher has a compact structure and is made of high-quality steel, allowing for long-term use.

2. High cleaning efficiency. This machine not only removes a high percentage of corn kernels, but also produces clean corn kernels.

3. Made of special materials, the newly designed roller inside the machine prevents damage to the kernels, ensuring that the kernels are ready for sale.

4. The corn thresher is easy to use and adjust, takes up little space, and produces high yields. Therefore, it is very popular both domestically and internationally.

5. Its flexible structure saves labor and time, allowing it to complete tasks such as threshing, winnowing, and screening

Work Principle

1. When the corn thresher is operating, the operator first places the corn into the feed inlet.

2. The corn enters the threshing chamber through the feed inlet, where the rotor strikes the corn kernels.

3. The drum, driven by the motor, rotates. As the corn enters the space between the two drums, it is threshed at an incredible speed.

4. The corn cobs are discharged from the rear of the corn thresher. Impurities such as husks are removed by a fan, which absorbs husks and other small particles, keeping the corn kernels clean.

5. The corn kernels fall through the screen. A baffle is installed below the inlet to prevent falling kernels from injuring people.

Note: The threshing efficiency of the corn thresher is determined by the length and diameter of the drum. The spikes on the rotor are easily damaged and should be inspected regularly. When the teeth are worn down to a quarter, they can be corrected with electric welding or replaced to ensure rotor balance. The screen is also a consumable part and should be replaced when damaged.

Application Scenario

Corn threshers separate corn kernels from corn cobs at an amazing speed while keeping the kernels intact. They are widely used in animal husbandry, farms and people's daily use.